Application of Water-Soluble Bending Lubricant in Automotive Exhaust Pipe Production

In the automotive exhaust pipe system, the bends are the weakest points, and the quality of their formation directly affects the performance of the entire pipeline. The plastic bending of pipes is a complex process involving material, geometric, and boundary condition non-linearities. After bending, various quality issues such as springback, thinning and even cracking of the outer wall, thickening and wrinkling of the inner wall, and cross-sectional distortion can easily occur. Therefore, in addition to selecting appropriate equipment and production process parameters, proper lubrication can facilitate the bending process, improve product precision, and extend the lifespan of the molds.

1.Customer's Challenge: Insufficient Lubrication Leading to Inaccurate Bending

The customer produces automotive exhaust pipes and supports brands like General Motors and Nissan. However, traditional emulsified bending lubricants often leave oil stains on-site, making them difficult to clean, and affecting subsequent surface treatment or welding processes. Additionally, some bending oils lack sufficient lubrication, which impacts product quality, resulting in issues such as inadequate bending precision and wrinkling on the inner side of the bends.

|

Automotive Exhaust Pipe Products |

|---|

|

|

2.Production Process and Principles

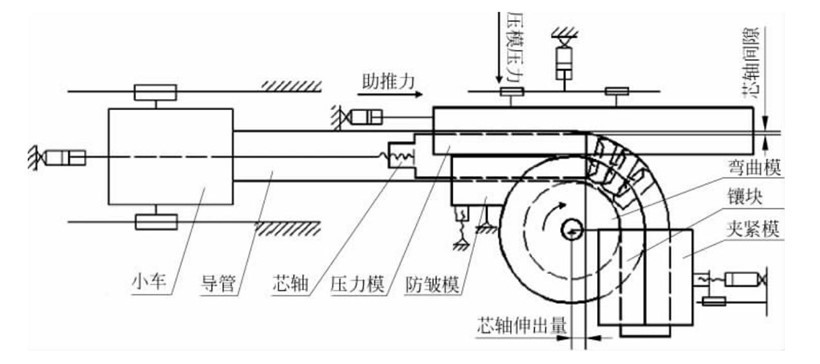

The metal pipes are bent into shape by a CNC bending machine under the specified parameters.

CNC Pipe Bending Process Diagram

Bending Process

3.Existing Problems

Standard bending oils fail to meet the requirements of the bending process, leading to insufficient product precision and issues like wrinkling on the inner side.

|

Inner Side Wrinkling |

|---|

|

|

4.Solution

We has introduced a water-soluble bending lubricant to replace the commonly used oil-based and emulsified lubricants, improving lubrication during the bending process.

5.Results

After switching to the company's product, the customer achieved stable bending quality when bending 1mm diameter stainless steel pipes, even with lightweight pipes (1820g) that previously tended to wrinkle. The new lubricant effectively meets the lubrication needs for pipe bending, ensuring consistent quality.

|

Before and After Comparison |

|---|

|

|