Exploring the boundaries

of fluid lubrication

We are a leading manufacturer of high-quality industrial lubricants and speciality lubricants with a wide range of industrial applications. We have a wide range of industrial experience.

We scientifically select suitable lubricants for our customers to meet the requirements of different equipment and different working conditions.

Product Category

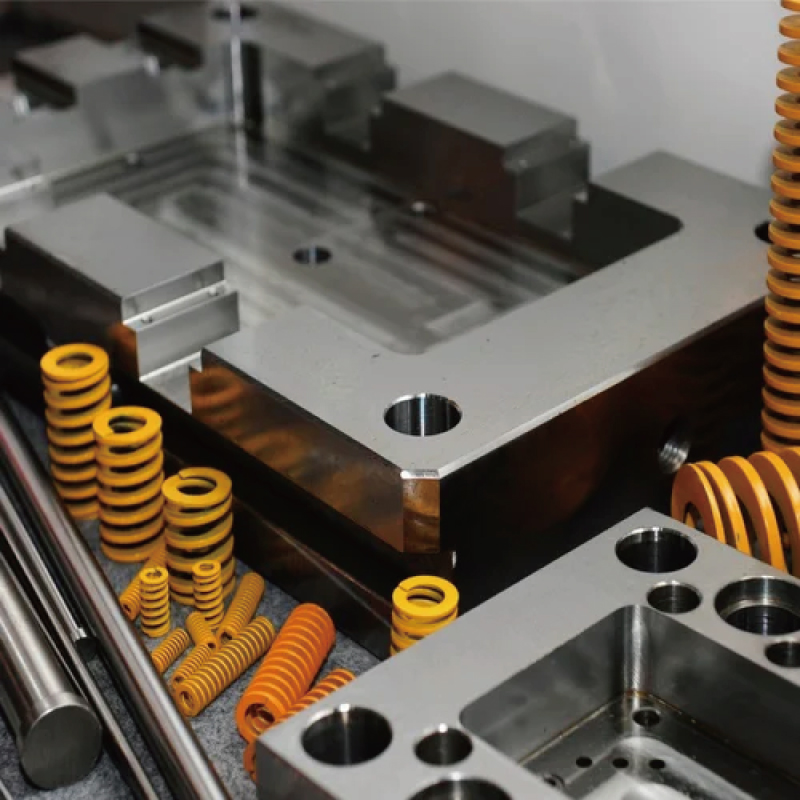

Our product range covers lubricants, greases, dry film lubricants, release agents and metal forming lubricants - more than hundreds of specialised customised products overall. High-performance lubricants greatly enhance environmental friendliness and equipment operability.

About Coomcool

Coomcool, a subsidiary of Ruixian (Shanghai) Chemicals Co., Ltd, is a leading manufacturer of high quality industrial lubricants and speciality lubricants, specialising in the research, development and design of industrial lubrication chemicals, with a wide range of industrial application experience. We have extensive experience in industrial lubricants and speciality lubricants. We select the right lubricants to meet the requirements of different equipments and working conditions.

New Arrivals

Our products meet high-quality standards and are highly reliable, making them widely used across various industries. Our experts leverage their extensive professional knowledge and on-site technical expertise to ensure the optimal performance of our products.

Featured Products

The most popular products from the collection

Ruixian (Shanghai) Chemicals Co.,Ltd

Our products include lubricants, greases, pastes, dry film lubricants, release agents and metal forming lubricants - a whole range of more than hundreds of specialised and customised products. High-performance lubricants significantly improve environmental friendliness and equipment operability.

Latest articles

Analysis of Common Causes of Chain Failure

Common chain failures include pin wear, corrosion, and overload, often caused by improper lubrication, misalignment, or extreme conditions.

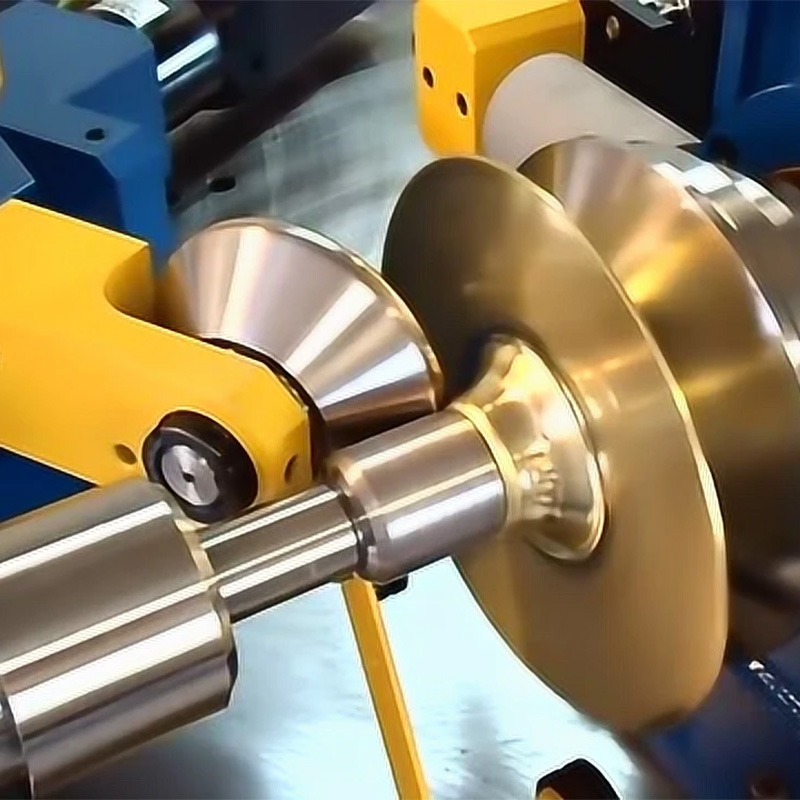

Principles, Classification, Characteristics, and Applications of Spinning Forming

Metal spinning forms high-strength, cost-effective hollow rotational parts using rotary pressure. It includes normal and power spinning, ideal for complex shapes and small batches.

Classification of Extrusion Processes

Extrusion processes are categorized by metal flow direction, material type, temperature, and product cross-section, with applications in various industries.

Causes and Countermeasures of Metal Corrosion

Learn the causes and types of metal corrosion, along with preventive solutions like passivation, coatings, and bacterial inhibitors.